The world leader in the production of protective materials for conveyor rollers and drums. Their materials provide better grip and longer service life compared to conventional rubber.

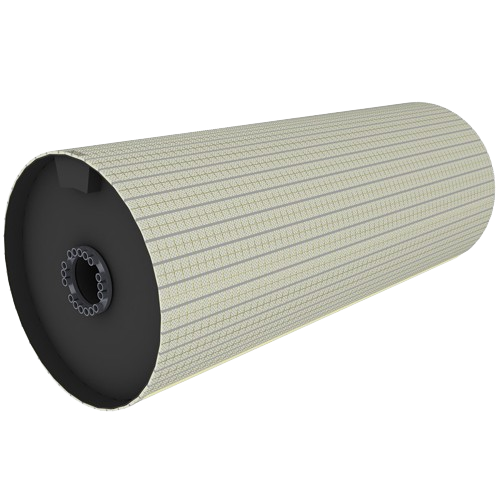

Protective materials for rollers and drums:

- Rubber lining

- Rubber-ceramic overlay with 38% ceramic

- Rubber-ceramic overlay with 80% ceramic

- Rubber-diamond overlay

- Extreme ceramic overlay

- Extreme rubber lining

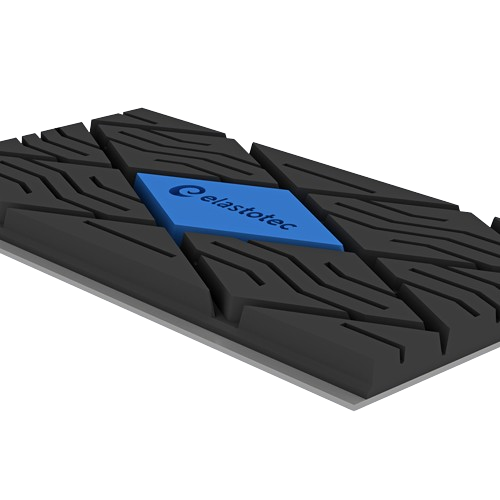

- Rubber pad with indicator

- Oil-resistant pad

- Polyurethane lining

- Crown plate

Elastotec Products

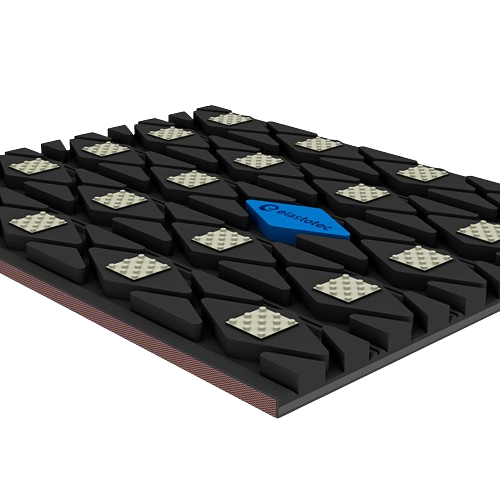

Diamond 15% Ceramic Lagging

Elastotec Diamond Ceramic Lagging is designed to provide additional grip in low to medium tension applications where existing rubber lagging is experiencing problems due to slippage.

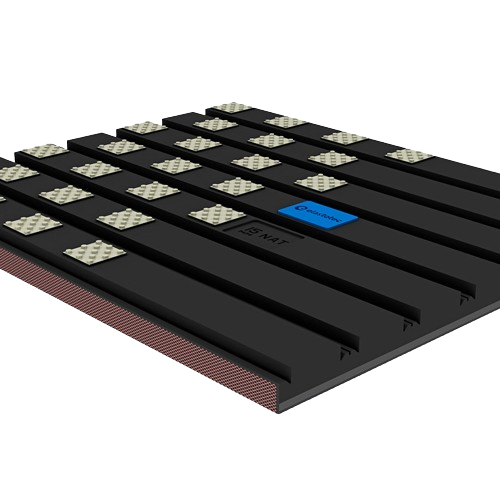

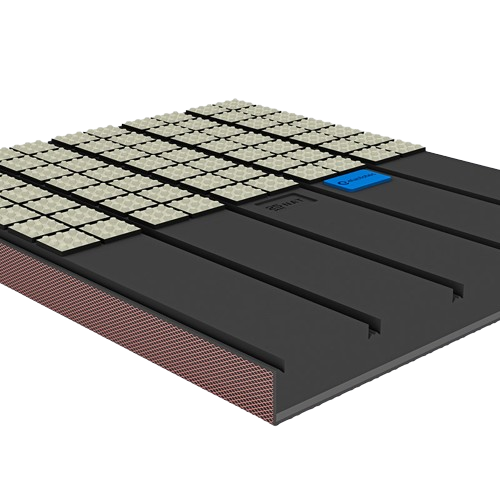

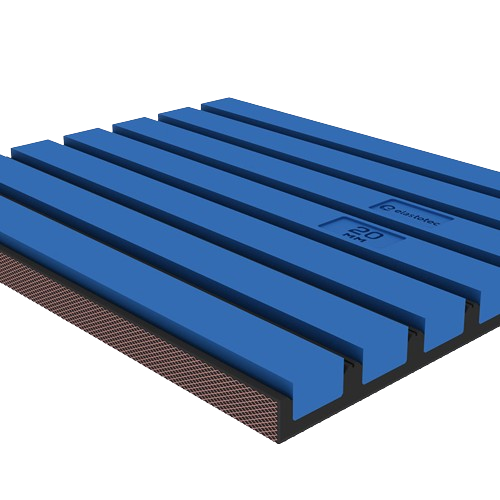

Checkerboard 20% Ceramic Lagging

Elastotec Checkerboard 20% Ceramic Lagging is designed to provide additional grip in low to medium tension applications and extra wear protection compared to Rubber Lagging.

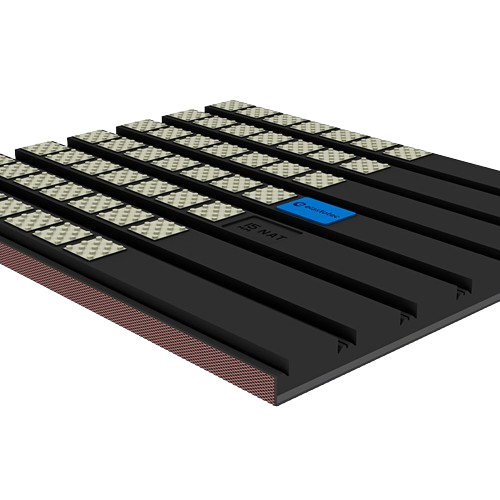

Medium Single Row 38% Ceramic Lagging

Ceramic Lagging provides a mechanical interlock between lagging and belt on drives and high abrasion resistance on non-drives.

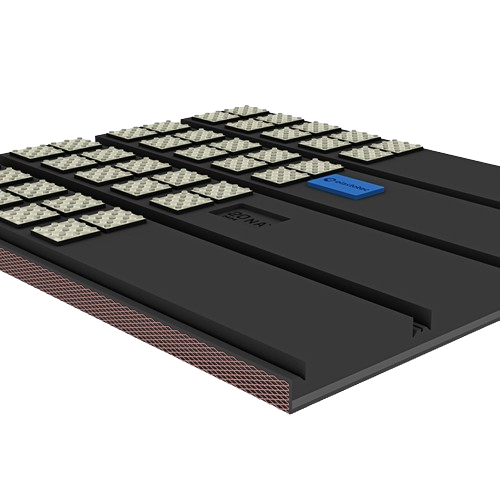

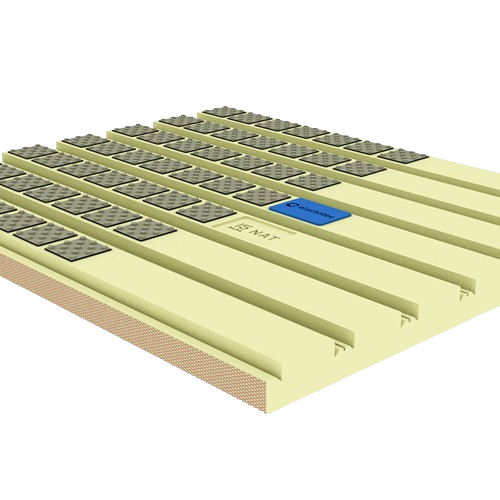

Medium Double Row 42% Ceramic Lagging

Elastotec Double Row 42% Ceramic Lagging provides a mechanical interlock between lagging and belt on drive pulleys, and high abrasion resistance on non-drives pulleys.

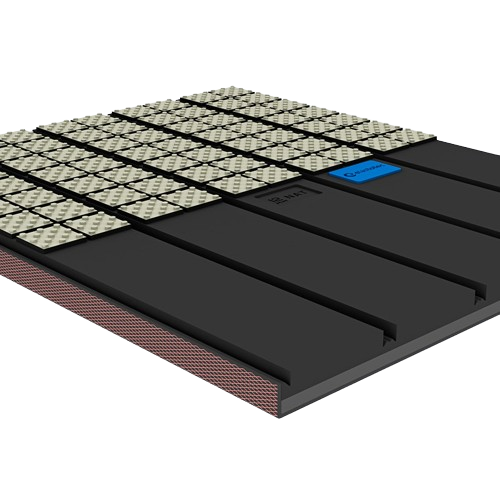

Full 80% Ceramic Lagging

Elastotec Full 80% Ceramic Lagging is designed to provide an increased coverage of 80% aluminum oxide tiles.

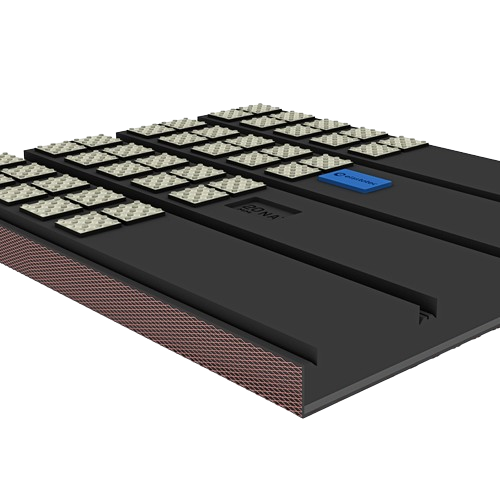

Extreme 42% Ceramic Lagging

Elastotec Extreme 42% Ceramic Lagging has an 42% ceramic coverage combined with a thick 8mm body ceramic tile with 1.5mm tapered dimples. It performs reliably in the following conditions:

Extreme 80% Ceramic Lagging

Elastotec Extreme Ceramic Lagging has been developed to provide mining companies with a lagging that will perform reliably in extreme conditions.

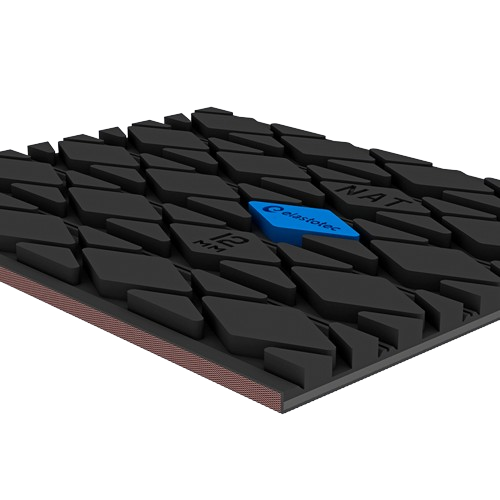

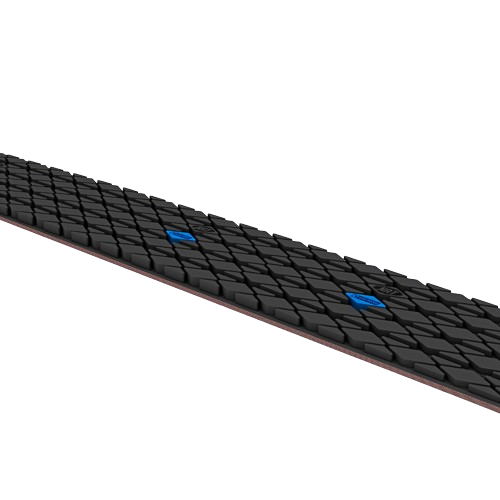

Diamond Rubber Lagging

Diamond Rubber Lagging is popular for increasing grip and reducing wear and corrosion of the pulley shell.

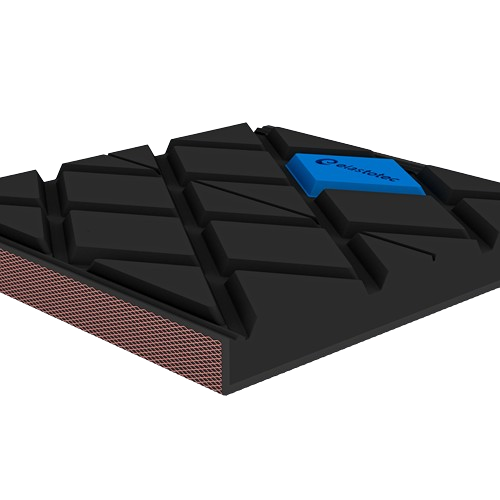

Extreme Rubber Lagging

Elastotec Extreme Rubber Lagging has been developed to provide mining companies with a long life lagging that will perform reliably on non-drive pulleys…

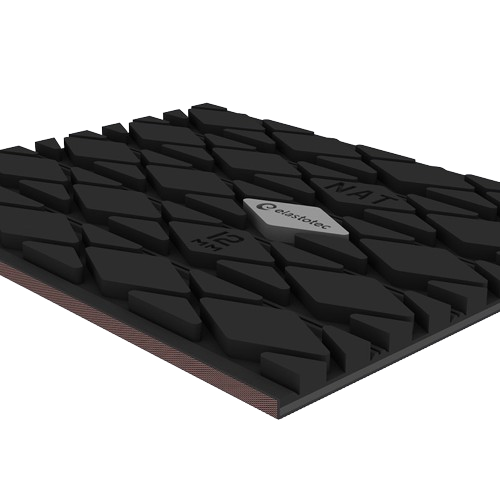

Wear Indicator Rubber Lagging

Wear Indicator Rubber Lagging is popular having a visual indication on when the lagging needs to be scheduled for replacement.

Crowned Rubber Lagging

Elastotec Crowned Diamond Rubber lagging is designed to provide improved belt tracking in low to medium tension applications where existing rubber lagging is experiencing problems.

Polyurethane Lagging

Elastotec Polyurethane Lagging is used to increase the service life of non-drive pulleys. Polyurethane’s extreme abrasion resistance combined with its low coefficient of friction provide a…

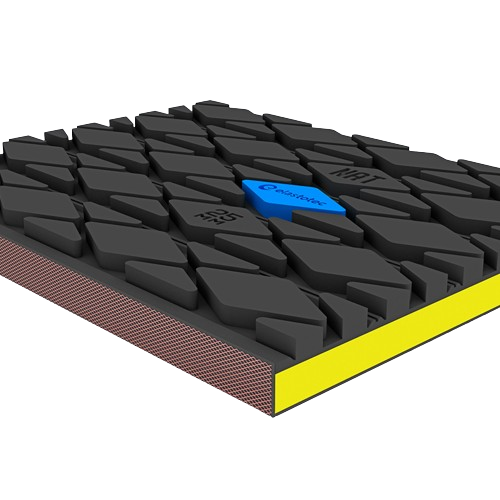

Oil Resistant Rubber and Ceramic Lagging

Why use oil resistant ceramic lagging?

- Longer service life when handling oily materials such as bitumen, tar sand and various grains.

- Resists tile loss due to oil resistant bonding system…

FDA Lagging

FDA Lagging is produced to comply with regulations to be used in the food industry.

Direct Bond Lagging

As a specialist pulley lagging manufacturer Elastotec has developed the Direct Bond Ceramic Lagging and method of application.

Slide Lagging

Elastotec Slide Lagging is a quick replaceable lagging system that has been designed to service a wide range of applications.

LLP “Lucrum Asia” Is An Official Dealer And Representative Of Factories-Manufacturers Of Equipment And Solutions Designed For The Mining Industry.

LLP “Lucrum Asia” Is An Official Dealer And Representative Of Factories-Manufacturers Of Equipment And Solutions Designed For The Mining Industry.

LLP “Lucrum Asia” Is An Official Dealer And Representative Of Factories-Manufacturers Of Equipment And Solutions Designed For The Mining Industry.

Copyright © 2024 LUCRUM ASIA, All Rights Reserved